Features

Large 190 litre bowl capacity and 120kg fresh trim batch capacity

5.5kW Helical Mince Drive delivers a more powerful performance ensuring efficient discharge whilst minimizing squashing or pulping of the product

Removable Stainless Steel Mixing Paddle enables thorough cleaning and sanitization (Quick Release, Heavy Duty)

Reciprocate Mixing Action ensures an efficient mix and dispensation of the product

Safety Interlocked and Counter-balanced Dome Lid complete with viewing grills (coded magnet

Compact Design with only 1223mm x 707mm of floor area required (excluding the barrel and accessories

42 Series (130mm) cutting head sizes

Low Loading Height (1069mm)

Smooth Corners and Surface Finish reduce cleaning down times.

24V AC control circuit

Full Overload Protection for motors

Heavy Duty Stainless Steel Castors (2 lockable) for mobility

High Quality 304 Stainless Steel machine body, barrel, feedscrew, lockring and mixing paddle

Fully Seam Welded Bowl - Welded both inside and outside

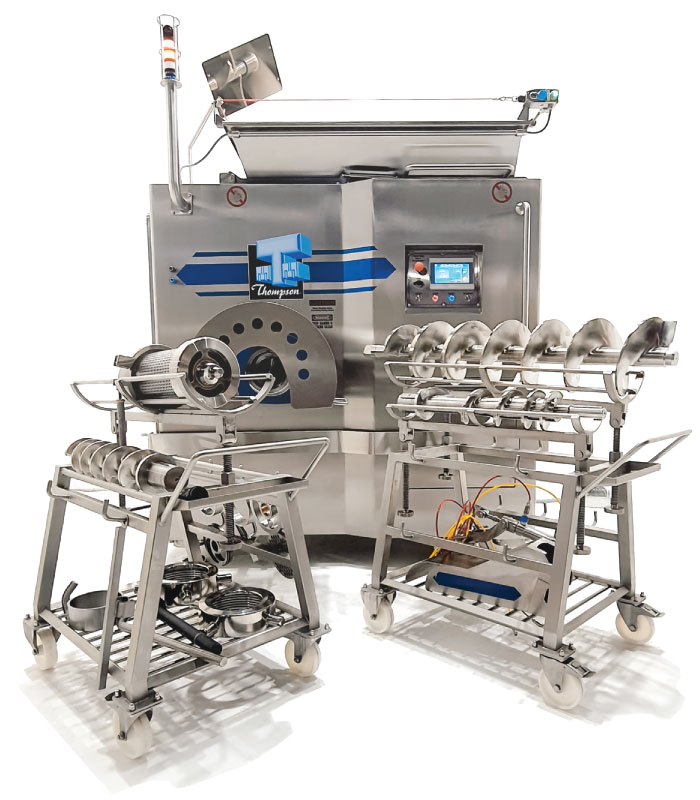

Photo Gallery

Options

7.5kW, 9.2kW Mince Motors

Foot pedal operation

Feedscrew knife and plate carriage

Gemini systems

De-bone / De-gristle cutting systems

Ingredients or liquid pouring channel to lid

Feedscrew ejector to remove feedscrew, knife and plate.

Description & Dimension

2000 Series Mixer Mincer

The Thompson 2000 Mixer Mincer is the next model up from 900 Mixer Mincer. It is designed to Mince Fresh Meat Expediently achieving excellent outputs and cutting performance with minimal increase in temperature on finished product.

Details & Characteristics

2000 Series Mixer Mincer

2000 Series

The Thompson 2000 Mixer Mincer has been engineered and manufactured to the highest specifications using the latest technology. Powered by 2 Independent Direct Drive Helical Reduction Units, the Thompson 2000 Mixer Mincer Delivers Years of Quiet and Reliable Trouble Free Operation. It helps the processors to achieve Excellent Productivity, More Efficiency, High Definition of Cut and Product Consistency.

Specifications (Based on 415 V / 50 HZ)

Mince Motor (KW)

5.5

Mix Motor (KW)

1.1

Bowl Capacity

190

Mix Capacity (kg) Fresh Trim

120

Power Supply (Amps)

20

Full Load Current (Amps)

14

Ship Size L x W x H (cm)

144 x 114 x 146

Ship Weight (kg)

440

Technical data is to be used as a guide only and is subject to change without notice. Dimensions and weight may vary in the course of development

Product Performance

Product

10mm Hole Plate kg/hour

5mm Hole Plate kg/hour

3mm Hole Plate kg/hour

Primary Cut

2,000

Secondary Cut

1400

Production rates are dependent on the product and temperature of the product

Videos