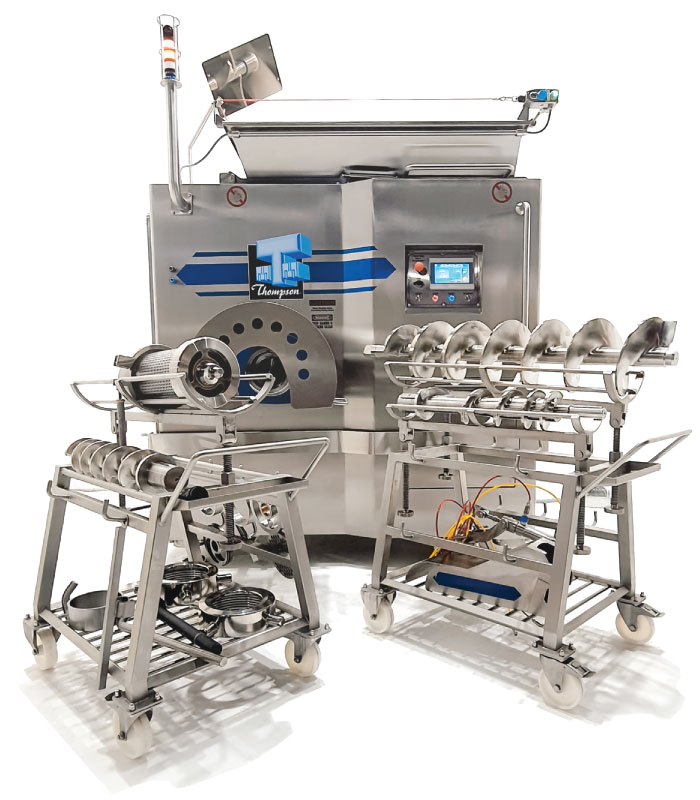

Thompson 42 Mincer

The Thompson Mincer is constructed from High Quality Stainless Steel, including the Barrel, Feedscrew and lockring, to ensure long life span and reliability in harsh environment.

The Thompson 42 Mincer has a genuine 114mm diameter feedscrew designed to mince fresh meat expediently through the 42 series (130mm diameter) mincing head.

The Thompson 42 Mincer higher production output rate reduces temperature rise, improves product shelf life, reduces labour cost and increases yield.

Removable Twist Barrel provides the most sanitary hygienic cleaning solution of the mincer barrel and feeding chute, which are difficult to reach by hand due to the safety guard.

The standard mincer is powered by a High Efficiency 4 kW Gear Motor Transmission. The electric circuit contains overload protection.

Thompson 42 Mincer

42 Series

The Thompson 42 Mincer is compact and designed to provide a cool and efficient mincing without squashing or pulping the product.

Thompson Meat Machinery offers a range of models in both appearance and working capabilities that enable the mincer to process a variety of products. These models have high production output rate of up to 2500 kgs/hour of minced meat.

The compact 42 Mincer uses only 700 mm x 800 mm of floor area (excluding barrel and other accessories).

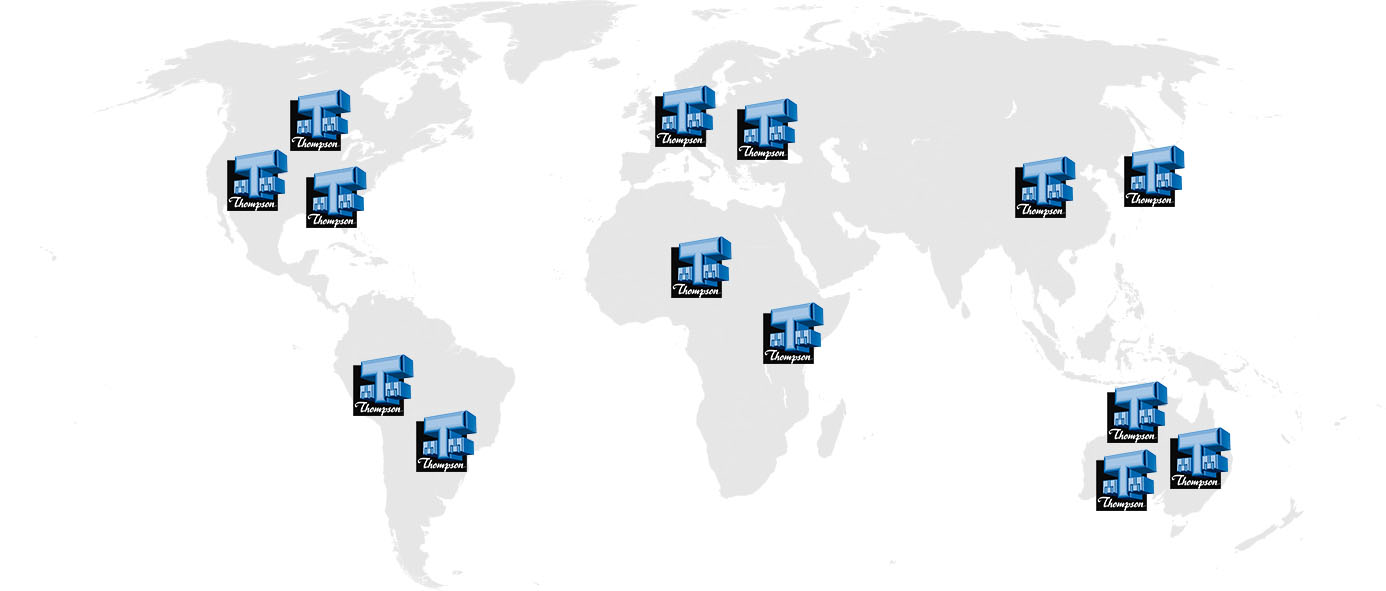

Thompson Meat Machinery is renowned for their custom design expertise built from over 30 years of industry meat processing experience providing customers with production solutions.

Construction

The Thompson Mincer is constructed from High Quality Stainless Steel, including the Barrel, Feedscrew and lockring, to ensure long life span and reliability in harsh environment.

The Thompson 42 Mincer has a genuine 114mm diameter feedscrew designed to mince fresh meat expediently through the 42 series (130mm diameter) mincing head.

The Thompson 42 Mincer higher production output rate reduces temperature rise, improves product shelf life, reduces labour cost and increases yield.

Removable Twist Barrel provides the most sanitary hygienic cleaning solution of the mincer barrel and feeding chute, which are difficult to reach by hand due to the safety guard.

The standard mincer is powered by a High Efficiency 4 kW Gear Motor Transmission. The electric circuit contains overload protection.