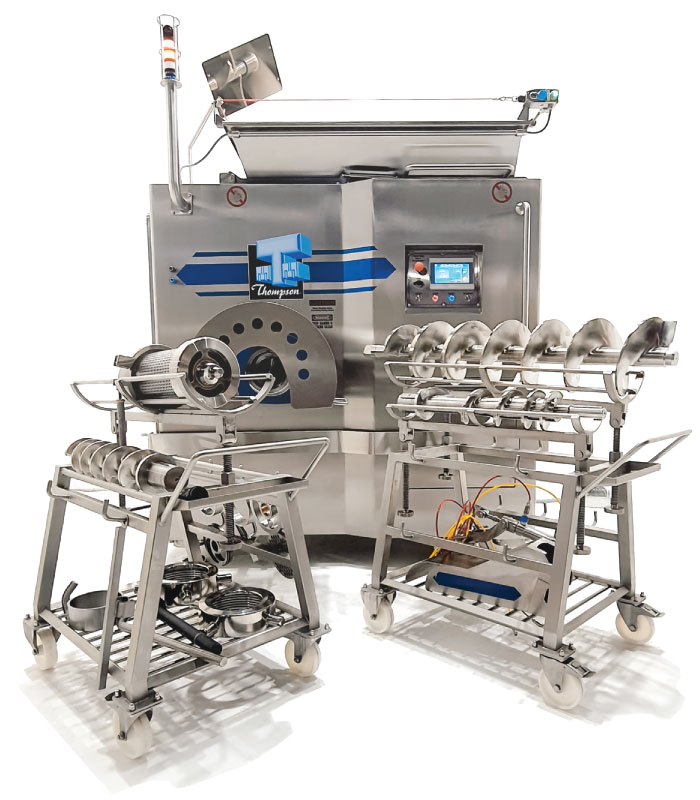

Bladestop 600 Bandsaw

BladeStop 600 Series II, the next generation in reducing

bandsaw risks, for large meat processing.

BladeStop reduces the risk of serious injury by stopping the

bandsaw blade within a fraction of a second.

The BladeStop 600 is a larger, heavy duty Bandsaw designed

to suit large processors and the cutting of large primals/carcasses.

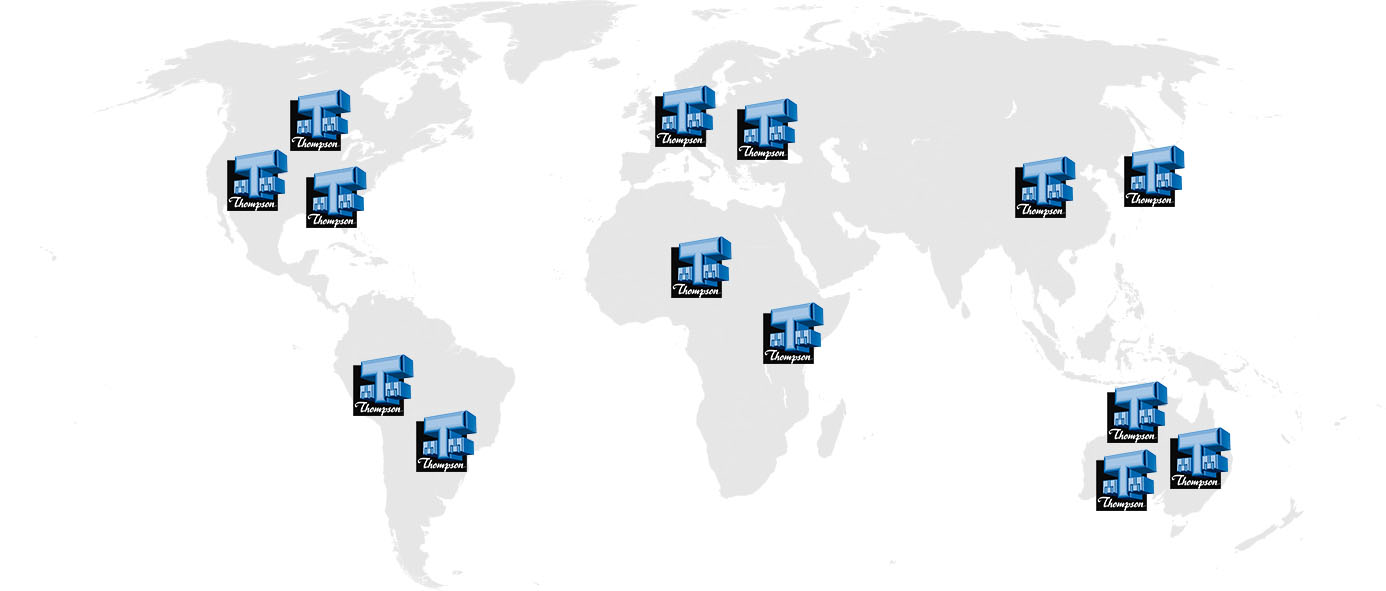

BladeStop™ is available worldwide and is uniquely designed

to reduce risks of serious injury by mechanically stoppin

the bandsaw blade when the unit senses that a person

has come in contact with the blade.

BladeStop is available in two sensing methods. Upon sensing

contact with the operator, the blade stops operating within

9 milliseconds. This can be a huge difference between having

just a small skin cut or an amputated finger.

Bladestop 600 Bandsaw

BENEFITS:

• Reduce production time lost due

to injuries

• Greatly reduce worker’s

compensation cost

• Reduce insurance premiums

• Reduce operator turnover and

training costs

• Promote positive OH&S related

to bandsaw operation

• Reduce product spoilage

• Improve personnel morale; happy

and motivated workers

• Improve company’s image as an

attractive workplace