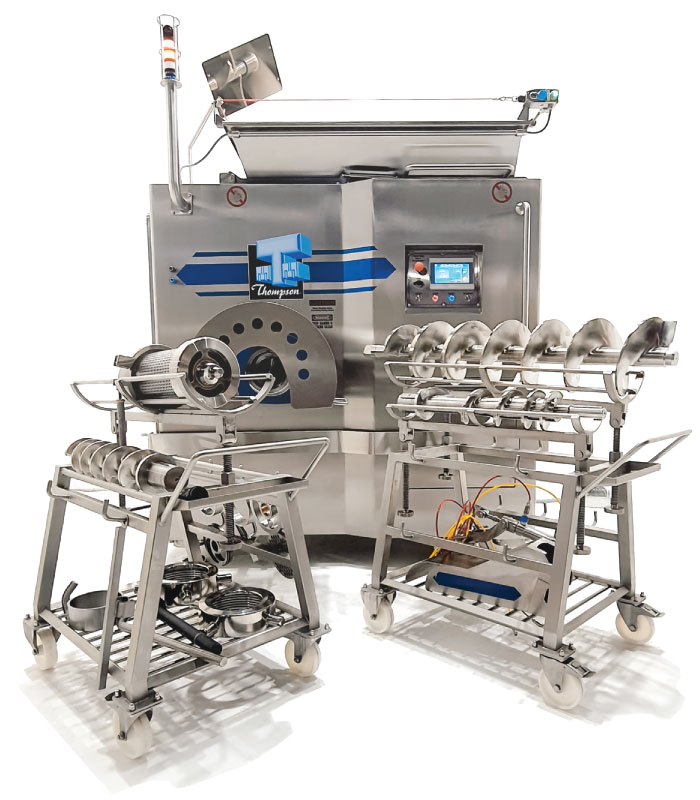

92500 Mixer Mincer

THE 9000 SERIES IS A NEW ADDITION TO OUR VAST MIXER GRINDER RANGE.

The key point of difference apart from improvements in our

gear motor drive technology is the feedscrew and cutting

system enlargement.

The 9000 series range of mixer grinders are in line grinders

whereby the feedscrew runs parallel with the mixing paddles

or right mixer grinders with the feedscrew running at right

angles to the paddles similar to the 5000 series.

There is no transfer screw feeding into a 2nd mincing

feedscrew like the 6000 series.

This short 170mm diameter feedscrew provides much higher

production output rates and with a High Efficiency Cutting

System (HECS) addition the ultimate grinding system.

9000 MIXER GRINDERS have been in operation since 2013

with the most recent developments of the 92500 Right Angle

Mixer Grinder (2500 kg batch capacity) and 91000 Straight

Mixer Grinder.

Beyond Spectacular Production output capacity is the 9000

series Mixer Mincer/Grinder Drive Train has undergone

significant engineering upgrades.

92500 Mixer Mincer

9000 Series

CO2 snow cones cooling system is used for processing batches

of product less than 300 kg through snow cones. This is a more

effective and efficient cooling system than bottom injection for

smaller batches. The bottom cooling injection system releases

a great deal of CO2 shooting at high pressure through the

smaller batches of product resulting an high amount of wasted

CO2 which is exhausted through the plenum by exhaust the

fan. The high pressure will also carry the product upwards

covering the internal surface of the lid making it more difficult

to clean. The CO2 bottom cooling injection process requires

an initial injection of CO2 gas to pressurise the manifold

system prior to the release of liquid CO2 into the chamber and

injected through the nozzles into the bowl. Once the liquid

injection process is complete a third process of flushing out the

manifold system with gas is necessary to complete the cycle.