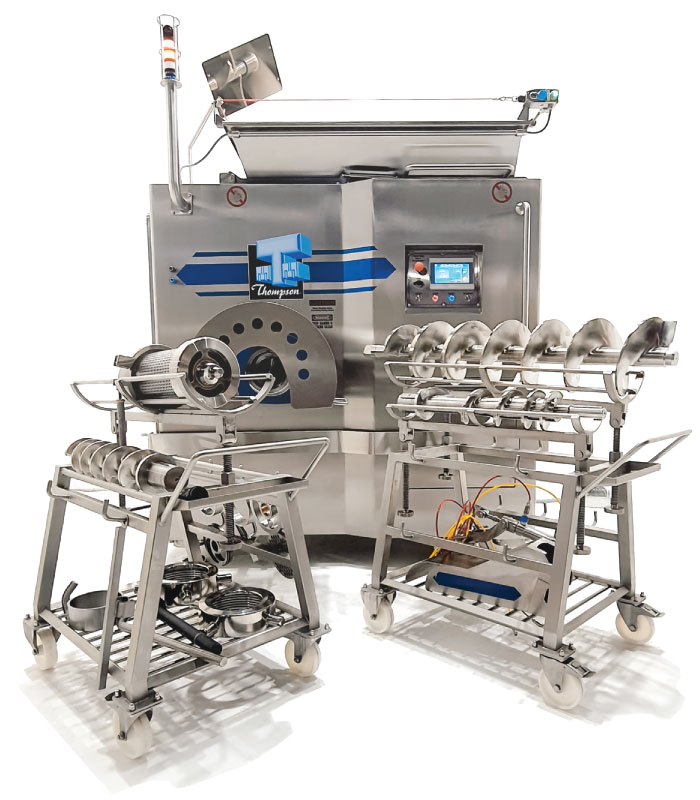

Thompson Mk6 Bandsaw

The THOMPSON MK6 BANDSAW is widely recognized for its uniquely designed Heavy Duty High Quality Construction and Performance. It is designed to offer Superior Low Maintenance operation in quality processing plants, supermarkets and butcher shops. With Quiet Operation and an Attractive Appearance, it

is ideally suited to a prominent position in shop fronts where the bandsaw is exposed to the public.

PERFORMANCE

The Efficient Design of the Thompson MK6 Bandsaw significantly improves the cutting action.

• Blade speed 910m/min (1.5kW), optional blade speed 1820m/ min (4kW)

• Cleaner cuts with reduced bone dust on product

• Portion cutting is straight and accurate

• Blade does not wander

• Cuts through frozen product (blocks) effortlessly

• Increases cutting efficiency and yields

CONSTRUCTION

Thompson MK6 Bandsaw is constructed from the Heaviest Duty Stainless Steel. The standard Stainless Steel Wheel and Blade Scrapers are fitted to reduce product build up between the wheels blades. New improved Blade Scraper design ensures safe and easy removal for thorough sanitation. Self aligning scraper also allows easy fitting after cleaning.

The Top Wheel is Removable for easy cleaning. The Top Wheel Housing is fully enclosed eliminating possibility of debris falling onto the table or product during operation. Bottom Wheel Motor and Flywheel Assembly fitted with direct drive system and Stainless Steel taperlock. This allows easy removal of bottom wheel and adjustment to eliminate possibility of the wheel seizing onto the Stainless Steel drive shaft creating additional maintenance.

Fully enclosed and improved Blade Tension Assembly with adjustable tension setting to the recommended blade tension through the life of the machine. It is located at low and easy to reach position.

Thompson Mk6 Bandsaw

SAFETY

Thompson MK6 Bandsaw offers features that Maximize Safety to the operator and other persons in close vicinity. Work Place Safety is a priority that should not be compromised.

Brake Motor allows the blade to stop within approximately 4 seconds when stop button is activated. This minimizes the possibility of accidents caused through blade run on, which is a mandatory

requirement of standards and regulations.

Brake Override Button allows the flywheels to be turned by hand for easy blade setup and machine maintenance.

Foot Controlled Stop Kick Switch enables the bandsaw to be stopped safely when the operator’s hands are full.

Limit Switches on doors, tilt-up table and bone dust bin ensure that bandsaw cannot be accidentally started during and after cleaning operations eliminating operator injury. Limit switches are internally wired to improve the safety, hygiene and appearance.

Purpose Designed Wheels are precision machined and balanced ensuring smooth, quiet and safe operation.

Removable Top Blade Guide is uniquely engineered with fine adjustment design.

Patented Bladeguard (optional) is a pneumatic blade guarding system that completely covers the bandsaw blade when it’s not in use. This mechanism is fast, effective and does not reduce any cutting efficiencies. It also prevents the motor from burning out in high stop and start operation situations.

EFFICIENT OPERATION

Start / Stop Controls are located at easily visible eye level for quick and easy access.

The Powerful Direct Drive System provides positive and constant blade speed and eliminates the requirements of frequent adjustments and replacement.

Powerful 1.5kW (optional 4kW) Motor ensures continuous smooth cutting operation through fresh or frozen products.

The High Clearance from Floor allows easy and thorough cleaning providing maximum hygiene. The Larger Bone Dust Bin provides increased bone dust holding capacity.

RECOMMENDED OPTIONS

• Bladeguard – Pneumatic Blade Guarding System