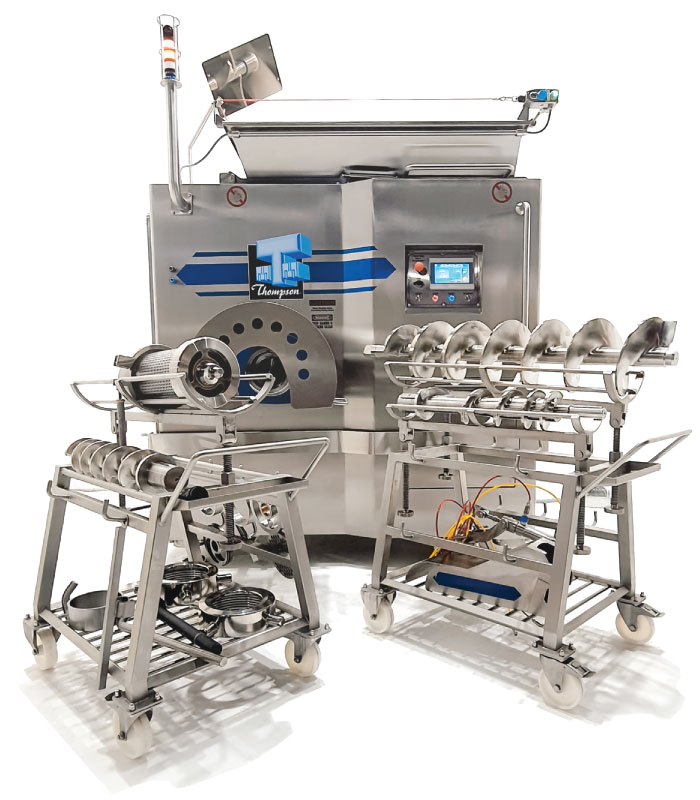

5000 Mixer Mincer Open Hopper

There are Huge benefits of incorporating Open Hopper and Extended Hopper to the Thompson 5000 Mixer Mincer. The Open Hopper fitted with Safety Trip Bar (illustrated in the photo above) allows the Standard Interlocked Lid to be removed. This allows continual loading of 200 or 300 L bins with loader or conveyor improves efficiency and increase production output rate from not stopping the machine when the lid is open to re-load product.

The Extended Hopper combined with the bowl increases total bowl volume from 530 L to 830 L. The Larger Extended Hopper further increases total bowl volume to 990 L.

Additional Hopper Capacity is of great benefit when processing frozen product that is generally either pre-broken, flaked or pre-ground. Frozen product volume increases by 2.8 times on average. A 200 L bin will generally only hold 70-80 kg of -10°C frozen flaked, pre-broken, guillotined, or minced meat. As the frozen meat is mixed efficiently and homogenously in the 5000 Mixer Mincer the frozen flaked or minced meat becomes more condensed and the volume is reduced ready for 2nd cut mince process.

5000 Mixer Mincer Open Hopper

5000 Series

The additional Hopper Capacity allows an additional bin to be added achieving a 200 kg and possibly up to 400 kg batch of finished product in the 5000 Mixer Mincer when using frozen pre-broken or guillotined meat.. The Larger Hopper Extension can easily accommodate 3 of 200 L bins of product.

The Extended Hopper also allows loading from the opposite end (gear motor drive end) when the 5000 Mixer Mincer is fitted with an End Discharge Chute.

The Open Hopper is fitted with Safety Trip Bar around the perimeter of the opening complying with Safety Standards. The Hinged Open Hopper also incorporates Safety Interlock to stop the machine operation when the Hopper is open, allows easy access to the bowl for cleaning and sanitation.