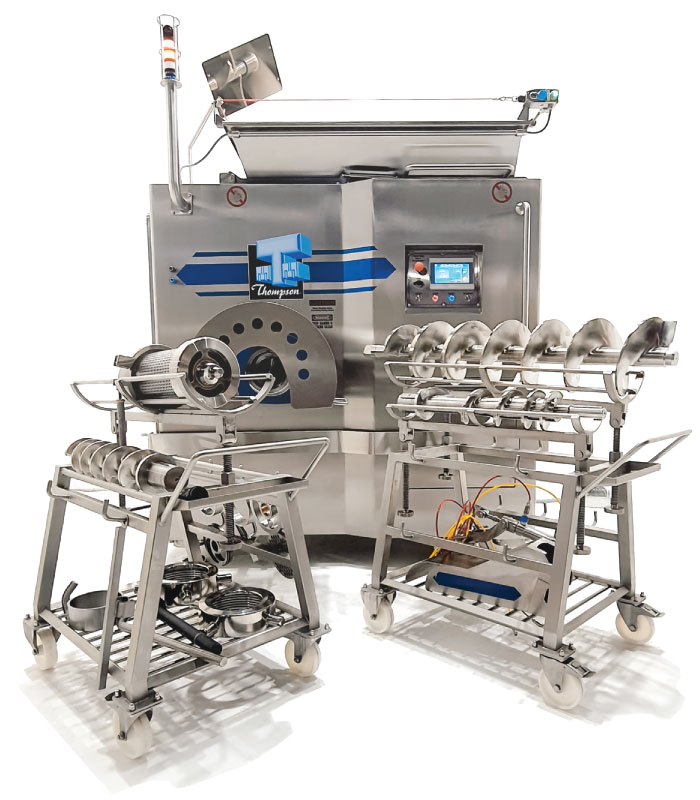

52000 Series Mixer Mincer

Thompson 52000 Mixer Mincer 3410 L Hopper Capacity available for customers with big demand, seeking productivity and efficiency gains with the requirements for 2000 kg batch mixing ability. Twin shaft overlapping mixing paddle system work extremely effectively and the mirror polishing finish on both the bowl and the paddles is very useful to limit any sticking of product to machine services. 52000 construction is further strengthened for the heavy loads and larger Torque required at times for mixing very heavy viscosity product.

The 52000-mince production rate of up to 8000 kg/hr is suitable with this batch size for many products in some instances pet food or Donna kebabs which lends itself to additional mixing tight binding product.

52000 Series Mixer Mincer

5000 Series

52000 Standard Design Benefits Include:

• Extended Hopper-Integrated

• Twin Shaft Overlapping Paddles

• 52000 S/S Cast Feedscrew Channel with Spiral Flighting

Increase Production Output Rate

INCREASED batch mix capability provides production efficiency from batch mixing time reduction over production day. Larger Total Hopper Capacity Allows More Bins to Be Loaded or use of Larger Bins to Be Loaded-Producing Production Time Reduction. Product load time reduction is a significant saving with immediate impact. Grinder/Process operator more available time for additional function.

Mix Batch 2000kg – Mince Production Output

• 1st Cut up to 8000kg /hour

• 2nd cut Mince 4 mm Hole plate 7500kg/hour

Improved Production Efficiencies, Increased Production Output, Production Cost Reduction