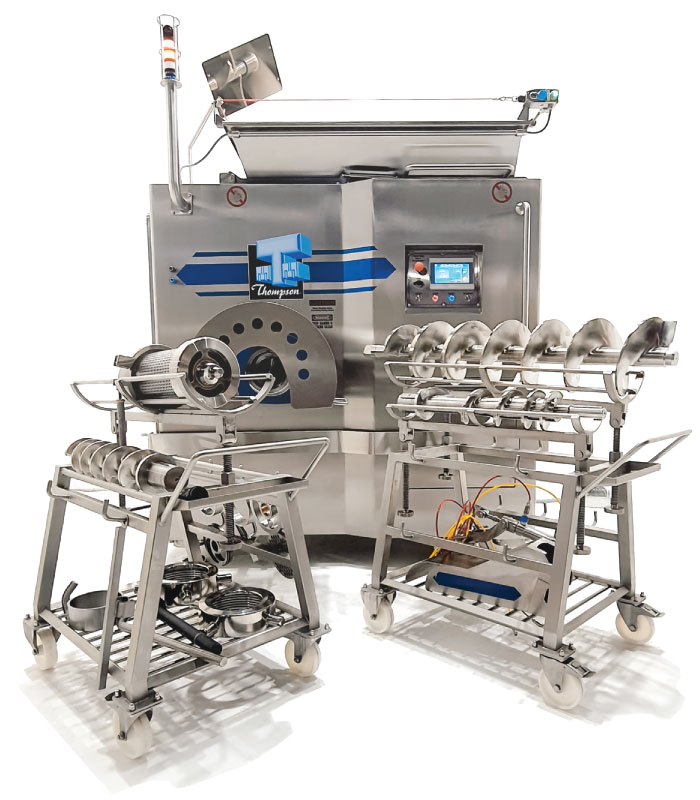

5000 Mixer Mincer Cryogenic Cooling System

Carbon Dioxide (CO2) Or Nitrogen (N2) Bottom Cooling Injection and CO2 Top Injection Through Snow Cones

Thompson Meat Machinery incorporates the CO2 or N2 injection cooling technologies in their mixer mincers, through a series of nozzles and manifold system which delivers efficient and consistent product temperature reduction technique coupled with perfect temperature controls.

CO2 snow cones cooling system is used for processing batches of product less than 300kg through snow cones. This is a more effective and efficient cooling system than bottom injection for

smaller batches. The bottom cooling injection system releases a great deal of CO2 shooting at high pressure through the smaller batches of product resulting an high amount of wasted CO2 which is exhausted through the plenum by exhaust the fan. The high pressure will also carry the product upwards covering the internal surface of the lid making it more difficult to clean.

5000 Mixer Mincer Cryogenic Cooling System

5000 Series

The CO2 bottom cooling injection process requires an initial injection of CO2 gas to pressurise the manifold system prior to the release of liquid CO2 into the chamber and injected through the nozzles into the bowl. Once the liquid injection process is complete a third process of flushing out the manifold system with gas is necessary to complete the cycle.

It is important that the manifold system stays pressurized until all CO2 liquid is ejected. If the CO2 goes below the critical pressure point it will form into a solid (snow) and block the complete manifold system. It can take numerous hours to defrost a blocked manifold system and that is why it is imperative that it is designed correctly. Thompsons have never had the issue of a blocked manifold system.

The N2 bottom cooling injection process releases small bursts of liquid nitrogen into the product. The large temperature difference causes the nitrogen to boil off as a gas which is used in the cooling process.

The program logic control (plc) temperature monitoring and control is fitted to regulate CO2 injection and maintain desired product temperature. Plc also monitors finished product temperature after mincing processes.